|

Repairing A Ceramic Firebox

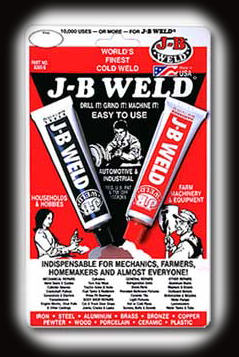

With JB Weld

Introduction

We recently discovered that the firebox in our medium Big Green Egg cooker had broken into a number of

pieces. We chose to repair the firebox using J-B Weld (pictured at right). We chose JB Weld becuase it is easy to use, will survive temperatures up to

(pictured at right). We chose JB Weld becuase it is easy to use, will survive temperatures up to

600°F, and once cured, forms a compound that is inert and safe to use in a ceramic cooker. So

we thought we'd document the process for you to show you how you can make these same repairs.

600°F, and once cured, forms a compound that is inert and safe to use in a ceramic cooker. So

we thought we'd document the process for you to show you how you can make these same repairs.

J-B Weld is a cold-weld compound, consisting of two different tubes of material that you mix to form the final product.

One tube contains a liquid steel/epoxy resin, while the other tube contains a hardener. Once mixed, the two

materials undergo a chemical reaction that results in a compound advertised to be as hard as

steel and resistant to heat up to 600°F. It sets in 4 to 6 hours and is fully cured in 16 to 24 hours.

Once fully cured, the resulting material is inert and safe to use to make repairs. (See the safety section

down below.)

You can read more about JB Weld at their website.

is a cold-weld compound, consisting of two different tubes of material that you mix to form the final product.

One tube contains a liquid steel/epoxy resin, while the other tube contains a hardener. Once mixed, the two

materials undergo a chemical reaction that results in a compound advertised to be as hard as

steel and resistant to heat up to 600°F. It sets in 4 to 6 hours and is fully cured in 16 to 24 hours.

Once fully cured, the resulting material is inert and safe to use to make repairs. (See the safety section

down below.)

You can read more about JB Weld at their website.

The subject of this operation is the firebox from our medium Big Green Egg cooker. When cleaning out the ashes, we discovered a crack

in the side of the firebox. When we tried to lift the firebox out of the cooker, we discovered that the crack went all the way around

the firebox.

The top half separated from the bottom half, the

bottom half fell back into the cooker, and broke into six pieces. Here is our poor broken firebox lying on the ground:

The Repair

While waiting to see if Big Green Egg would replace our firebox under the warranty (we had never registered it or kept the receipt),

we decided that we could fix our firebox with JB Weld which would give us the opportunity to document the process for you.

So, how do you prepare the JB Weld for gluing? It's pretty simple:

But before you begin mixing and gluing, you should thoroughly clean any edges that you will be joining

with the JB Weld, and develop a plan of attack by piecing together all the broken pieces

first and determining the order in which you will attach them. A ceramic firebox is a relatively complex shape and

you will find it easier if you attach certain parts before others. You may also have to get creative in finding a way

to hold pieces in place for the 4-6 hours it takes for the JB Weld to set.

You now have plenty of time to apply the JB Weld and fit parts together since the JB Weld won't set for a few hours.

So, it's just a matter of slathering the JB Weld on the edges you wish to join and then pressing them together.

When you are done, you will have a complete firebox. It may not look pretty, but it will do the job.

Once you have safely got all the parts stuck together, let it all sit undisturbed for 24 hours to let the JB Weld

fully cure. Then you can put your firebox back in your cooker. We lit a small fire and let it burn until the

charcoal was used up. We let the firebox cool and then we filled it with charcoal and let it burn at a fairly

high temperature until the charcoal was used up. You will notice that any JB Weld that had oozed out of the gaps

on the inside of the firebox will burn away. This is to be expected since JB Weld is only good to 600°F.

However the remaining JB Weld will still hold things together.

Safety Information

If you have safety concerns about using epoxy and hardener in a cooker, we contacted JB Weld and they

directed us to this entry in their FAQ:

"When fully cured, J-B Weld is non-toxic. Our products are not rated food-safe, and we do not

recommend consuming the product or using it on areas that directly touch food or beverage."

So we have the usual "it's not rated food safe" warning, but all that means is that since it isn't

intended to be used in direct contact with food, they don't test it for food safety. And since they

don't test it for food safety, they can't make a recommendation. Also notice

that the warning only goes on to say that they don't recommend it be used if it is going to

come into direct contact with food. We take from this that it is perfectly safe to use JB Weld

to repair components of ceramic charcoal cookers.

It is probably a good idea to do a relatively hot burn in the firebox to burn away any JB Weld that has

oozed into the firebox. This will ensure that if the burning JB Weld does emit anything toxic, it will

be gone before you start cooking.

|

UPDATE: Does it smell?

We were alerted by a reader to the fact that cured JB Weld material may emit an odor

once it is heated above 400°F. We hadn't noticed any smell while heating up the

firebox initially, but we respect this reader so we decided to look into it further.

Here's what we did and what we found out:

- Once the firebox was cured, we lit a small fire in our cooker and let it burn

out. We never smelled anything but charcoal/smoke during this burn.

- After the cooker had cooled down, we burned a full firebox of charcoal with the

vents wide open. Again, during this process we never smelled anything but

charcoal/smoke.

- We did a third hot burn and yet again, we smelled nothing other than charcoal/smoke.

- At this point we began to wonder if any odor being emitted by the JB Weld was being totally

overwhelmed by the smell of charcoal/smoke. So, we placed the firebox in our oven and heated it up to 450°F.

We noticed a slight chemical smell. Of course, by this time, the firebox had been heated up four times, so

we decided to try again with some freshly cured and unheated JB Weld.

- We mixed up a batch of JB Weld in an aluminum

foil pan and let it cure for 36 hours at room temperature. We then placed said pan in our

oven and set the temperature to 300°F. No smell. We bumped it up to 400°F and began

to notice a chemical smell. Finally, we bumped the oven up to 500°F and sure enough, the

smell became quite noticeable. So clearly, the smell of the burning charcoal was able to

totally obscure any chemical smell from the JB Weld itself.

- Our next question was how long this smell might persist. Is it possible to heat the JB Weld

and "drive the demons out"? So we let the JB Weld cool and sit for another 24 hours before

once again heating it up to 500°F. Sure enough, after 3 cycles of heating the cured JB Weld,

the smell was almost gone.

|

So yes, JB Weld will emit an odor when heated, but this odor will disappear after a period of heating

over 400°F. So again we conclude that JB Weld is indeed safe to use and again we will point to the fact

that JB Weld only cautions about letting food come into direct contact with the cured material because

they haven't tested it for food safety.

.

|

|