|

|

In the following photo we have turned the system unit on its back and show the bottom where the connectors are:

The connector on the right is for power. You can either use the supplied "brick" power supply or they also sell a cigarette lighter adapter that you can plug into one of the many automobile starter batteries available which have a cigarette lighter outlet on them. The plug on the adapter must have a positive center connector. The connector in the middle is for the temperature probe. And the elephant in the room is that big black hose on the left. That is the air hose which passes the air from the integrated blower into the cooker. The hose is quite substantial, and although the hose fits nice and snugly over the tube on the adapter plate, there is also a clip which can be used to ensure the hose doesn't come off. The hose is permanently attached to the iQue 110 unit. The iQue 110 comes with a temperature probe for monitoring the cooker temperature:

The probe itself is made from stainless steel and contains a platinum RTD sensor rather than a thermocouple that other brands have. What's a platinum RTD sensor? You may wish you hadn't asked, but here goes. First of all, a thermocouple works on the Seebeck effect. When two ends of a conductor (wire) are at different temperatures, a voltage is created between the two ends. The magnitude of the voltage depends on the temperature difference between the two ends. If you take two conductors made from different materials, there will be a different voltage created in each conductor. Then if you connect the two conductors at one end, the two voltages will add producing a voltage across the two conductors that varies with temperature. With me? If you know the materials, then you know the voltage generated for each temperature and this then gives you the DIFFERENCE in temperature between the two ends of the pair of conductors. Finally, you put a thermistor inside the meter that the probe plugs into to tell you the temperature of that end of the pair of conductors. Voila! You know the temperature of one end of the pair of wires, and you know the temperature difference between the two ends. Therefore you know the temperature of the other end! Simple, eh? Well, platinum RTD sensors work like this. Many materials have an electrical resistance that varies with temperature. So if you can measure the resistance, you know the temperature. Platinum is a popular material for this type of sensor. You pass a small current through the sensor, measure the resistance and deduce the temperature. What's the difference? Thermocouples are faster reacting and can measure much larger temperature ranges. RTD sensors are more accurate and more stable. So we asked the maker of the iQue 110 why they chose to use RTD sensors and it turns out that an RTD sensor does not need to be calibrated to the unit. A thermocouple should be calibrated to the unit being used. In light of the fact that the iQue 110 has no numeric temperature readout, you can't really calibrate it. Having a probe that doesn't need calibration is therefore pretty much a necessity. Also, the reponse time is not a critical factor in this application and the RTD sensor is more accurate. The wire has an armor braid and can withstand temperatures up to 500°. Be careful not to kink the wire. The junction where the wire enters the probe appears to be sealed, but the manufacturer recommends that you avoid getting this junction wet. The probe and the wire should be shielded from direct radiation from a hot fire. Do not let it come into direct contact with flames. If you need to shield the wire, you can place a layer of aluminum foil beneath it. Also, having the pit probe itself exposed to direct radiant heat can cause it to register a temperature which is higher than the air temperature in the cooker, and thus fool the controller into cutting back on the fire. (If a probe does fail, you will be able to tell because when plugged into the controller with no heat applied to the probe, the controller LED will blink alternating red and green.) An alligator clip is provided which you can use to clip the probe to your dome thermometer or the food grid, as you see fit. How accurate is the probe? Since the iQue 110 has no temperature readout, we cannot measure the accuracy of the unit directly. We will have to wait until we test the unit to see how close to the target temperature the iQue 110 can hold the cooker. However, in general as we stated earlier, platinum RTD sensors are more accurate than thermocouples. RTD sensors don't require calibration, so there is no procedure for calibrating the unit. Now let's take a look at the blower which feeds air to the fire in the cooker. First off we have photos of the blower and the adapter:

It should be obvious that you are looking at the first temperature controller to utilize an integrated blower. No separate blower and extra wire to manage. The blower is a variable speed blower which is controlled by the unit to deliver between 5 and 15 CFM, as the situation requires. The adapter is made from aluminum and is indeed aluminum colored. We managed to achieve the colorful effect in the photo above by not paying attention to what we were doing with the lighting and the camera. The rubber hose from the iQue 110 just slips snugly over the tube in the adapter, and the adapter fits into the grooves of the lower vent on the Big Green Egg. The adapter is a bit of a pain to install and remove as you must bend down the tab at the end of the Big Green Egg lower vent in order to slide the adapter in. Then you have to bend the tab back up to slide the adapter snugly to the left. We much prefer the adapter used by BBQ Guru which can be slid in and out without having to bend anything on the cooker. Also, while the adapter will also fit on a medium Big Green Egg, the vent on a medium Big Green Egg cooker has a sharper curve to it and you may find you have to bend the iQue 110's adapter a bit to help it fit into the curve. pitmasterIQ.com has other adapters available for other brands of cookers.

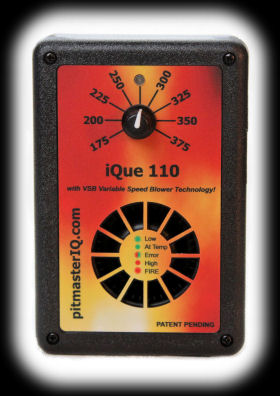

The iQue 110 has no audible alarms. All communication about the status of the controller is done with the LED. |

You can support this website by shopping at The Naked Whiz Website Store and Amazon.com

|