The barbecue temperature controller market was pioneered and has long been dominated by The BBQ Guru's line of controllers which have included the NanoQ, the DigiQ, the CyberQ, the CyberQ Wifi, the PartyQ, the PartyQ II and the ProCom4 controllers. They have been selling controllers since early 2004. They were followed in 2006 by Rock's Barbeque and The Stoker controller which introduced internet connectivity, web-based control and multiple cooker control. In early 2010 another company, Auber Instruments, entered the arena with a low-cost simple temperature controller. In October 2010, yet another company appeared at The Jack in Lynchburg where they introduced yet another temperature controller, selling their first four units.

That company was pitmasterIQ.com and the temperature controller they were selling was the iQue 110 temperature controller which is, unless we are mistaken, the first all-in-one barbecue temperature controller to hit the market. The controls, the blower, everything was contained in a single unit. The only thing that wasn't part of the unit itself was the temperature probe which goes inside the cooker. As a temperature-control-only unit, it compared with the BBQ Guru NanoQ and the Auber Instruments controller.

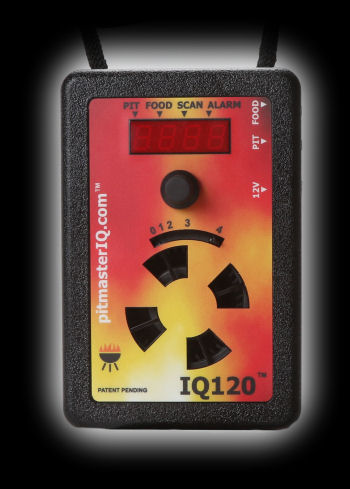

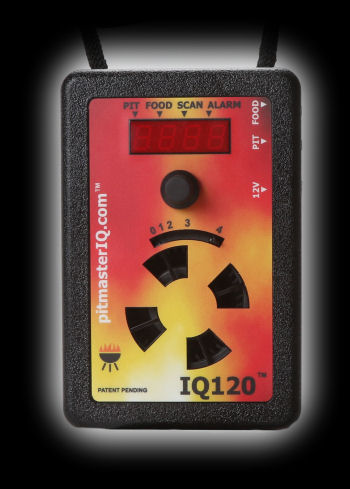

But now pitmasterIQ.com has brought out the IQ120 which brings more features to the cooker. There is now a display, configurable settings and a food probe. We'll go into more detail obviously, but the IQ120 brings pitmasterIQ.com into the next tier of temperature controllers. So let's take a look!

Features

Here is a list of features and specifications:

- Programmable - automatically change cooking temp based on food temp and/or time

- Precise temperature control with a single setting, 150°F to 400°F and anywhere in between. Keeps cooking temperature within 5°F of set point

- Open lid detect

- Programmable "Food Done" alarm

- Programmable "Pit Set" alarm sounds when cooking temperature deviates by more than setting

- Programmable settings for fan speed, temperature units, beeper volume, and display brightness

- 4-digit 7-segment LED display

- Rotary digital encoder control for making programming adjustments

- 5 CFM to 15 CFM Variable Speed Blower

- Color coded probes with platinum RTD temperature sensors good to 0.2% with 6' cables

- Installs on Big Green Egg, Weber Kettle, Weber Smokey Mountain, and most other pits

- Designed/manufactured in USA by Digital Power & Motion, designers/manufacturer of industrial controls

- AC adapter: 100-240VAC. 50-60Hz power supply with 6 foot cord. 12VDC 1.0A output. 5.5mm OD, 2.1mm pin, center positive plug.

- Optional cigarette lighter 12VDC adapter

- Controller dimension: 4x6x1.5". (2.25" thick if you include the control knob.)

- Integrated 24" air hose.

- Operating temperature range: 0°F to 140°F.

- Operating humidity range: 0% RH to 95% RH, non condensing.

- Price includes unit, pit probe, food probe, power supply and cooker adapter.

- Warranty: 180 days

- The unit is plastic and is not water-resistant. It can be operated in wet conditions using something like the Rain Box project shown on their web site.

- The adapter for the large or medium Big Green Egg (which we will be testing) is constructed from stainless steel and includes a clip to assist inserting the plate into the grooves in the lower vent frame.

- The temperature probe cable should be able to withstand temperatures up to 500°F. It must be kept 24" away from any flame.

Compared To Other BBQ Temperature Controllers

Whereas the iQue 110 clearly fell into the same category as the Auber Instruments controller and the BBQ Guru NanoQ (all three units intended to be simple, low-cost temperature controllers), the IQ120 has added a load of features that puts it into the same class as some of the BBQ Guru models and the Stoker. It now has a food probe for food temperature monitoring. The presence of a food temperature monitoring means you now can monitor the temperature of the food and have a form of Ramp Mode. There's no wireless, no dual-cooker control, no USB connection, but you now can monitor and control both your pit and the food with one unit.

The Basic System

Here's what comes with a basic system:

- The IQ120 integrated controller/blower unit

- Pit and food temperature sensors

- Power supply

- Blower adapter (which you select when you place your order)

- Hose clamp and kill plug

- Printed User Guide

When you order your system, you specify the type of door adapter you need. The door adapter is included in the price of the system.

A Few Observations About The Components

Like the IQ110 controller, the components which make up the IQ120 appear to be top notch. The control unit is sturdy and rugged. The damper has positive stops at each setting. The cord atop the unit feels strong and subtantial. The control knob feels precise in its movement and pressing it to activate options provides feedback that you have pressed it adequately with a click. The air hose is heavy and substantial. The temperature probe cables are steel braid. The power supply can be gripped firmly to plug and unplug it from a power outlet. Overall, you get the feeling that the unit is quite well built.

The System Unit

The system unit is a small plastic box about 4" x 6" x 1.5" in size which weighs in at just over 20 ounces. The case is made from polycarbonate, one of the toughest and most heat resistant plastics out there. The case encloses both the electronics and the blower and has an air hose attached which feeds the air from the blower into the cooker using an adapter made for each type of cooker. The housing is not water resistant, so precautions should be taken when using it under the threat of rain, such as using a plastic box as shown on the pitmasterIQ.com web site. We typically place these types of units in a zip top plastic bag. Of course if you do use a bag, you must ensure that the blower doesn't suck the bag up against the opening or there will be no air blown into the cooker. The unit has a loop of heavy cord which can be used to hang the unit from the cooker handle or any hook within reach. All the controls are on the front panel, while the plugs for power and the temperature probes are on the side. Also, note that the back has a handy quick user guide.

A couple of notes about the system unit. First, we asked about the blower intake and what would happen if it were obstructed. We found out that this actually “unloads” the blower, causing it to do no “work” (pushing no air). It is a common misconception that this is bad for the blower when in fact it is not. Also we were informed by pitmasterIQ.com that they have no reports of debris being sucked into the blower and causing damage, but it is probably wise to do your best to prevent debris from getting into the blower intake.

Second, you may wish to hang the unit from your cooker's handle, so what about the unit's ability to withstand heat? From the pitmasterIQ.com FAQ:

Q: Is the IQ temperature resistant?

A: Yes, when used according to instructions, the iQue will not be damaged. If the iQue is on a pit and the temperature ramps up very high, due to a grease fire or improperly starting the pit, the iQue may be damaged. In this case, the warranty will be void.

So it sounds like if you use some common sense about exposing the unit to heat, there should be no problem. There is also this statement in their FAQ specifically about hanging the unit from a handle:

Q: Can I hang the IQ from my pit?

A: Only if you are running the pit at 250°F or lower, and the IQ's enclosure is at least 1" away from the pit, and the fire is not built directly behind the IQ's enclosure. If on a kettle, the fire must be built for indirect cooking in the REAR of the pit. If the metal behind the IQ's enclosure is too hot to touch for 1 second, then it is too hot to hang the IQ there. Instead, set it on the ground or a small table. Overheating the enclosure will void the warranty.

The unit does have a temperature sensor in the system unit to sense an over-temperature condition and it will shut down the blower (i.e. to stop fanning the fire) if the unit gets too hot.

Controls and Display

Let's look at the front panel details. In the photo below, you can see unit display, control knob and blower damper adjustment:

First, the LED display. The display has four 7-segment LED elements. Each element also has a dot in the upper left corner. The dots tell you if the display is showing you the pit temperature or the food temperature, as well as telling you if the display is in scan mode and if there is an error or notification:

|

Here the unit is displaying the pit temperature as indicated by the PIT element being illuminated. Also, you can see that the display is in scan mode (where the display alternates between the pit temperature and the food temperature) as indicated by the SCAN element being illuminated. And of course, you can see that the pit temperature is 93°. |

|

Now the display is showing the food temperature as indicated by the FOOD element being illuminated. The display is still in scan mode and the food temperature is 77°. Also note that in this photo and the previous photo, you have some segments of the left-most digit lit up. This is the virtual blower feature that tells you that the blower is actually operating. (More about this later.) The segments around the edge of the digit light up in sequence around the digit. If the blower is off, all the segments will be off. |

|

This is an example of an alert. The ALARM element is illuminated telling you that something is wrong. The PIT temperature is being displayed at the moment, but this display will alternate with a scrolling message to tell you what's wrong. |

|

This is an example of a scrolling message. We opened the lid of the cooker to let it cool off and the unit detected the rapid fall in pit temperature. Thus the unit began alternating between the previous display and scrolling the error message, "Lid Off". |

One other feature of the display is that it has a 5° snap for the pit temperature. In other words, when the pit temperature is within 5° of the target temperature, the display automatically changes to showing the target temperature. Also, the display is capable of showing temperatures from -18° to +540°F, however remember that 540°F is a bit beyond the safe maximum temperature for the probes.

Next, the control knob. Whereas the IQ110 had a rotary potentiometer which rotated through about 270°, the IQ120 has a rotary digital encoder. Rather than a smooth continuous rotary motion, you feel the knob rotating through a series of clicks, and the knob will rotate in either direction without hitting a stop at each end. Rotating the knob is used to scroll through menus, adjust values, etc. The knob can also be pushed and you will feel a click as you press the knob. This is how you select a menu item or a value for a parameter.

Finally, the last control on the front panel is the blower damper control. There is a tab that can be slid side to side from setting 0 to setting 4 in order to close the damper to varying degrees. If you find that the blower is too powerful for a small cooker or a particularly efficient cooker, you can close the damper down to limit the airflow beyond what the control algorithm can do on its own.

|