|

|

The item(s) contained in this review were purchased by The Naked Whiz website,

using funds sourced from reader donations and web site advertising. No considerations,

financial or otherwise, were given to or received from Soapstone Products.

Introduction

Soapstone (also known as steatite or soaprock) is a type of metamorphic rock. It is composed largely of the

magnesium-rich mineral talc. It is durable, heat-resistant, non-porous and has a high heat storage capacity

and has therefore

been used for cooking for thousands of years. Soapstone pizza stones are not just for cooking pizza.

You can cook steaks, smashburgers, scallops and any number of foods that benefit from a hot cooking

surface. So is it any wonder that Kamado Joe, one of the industry leaders in

producing accessories for their kamado-style cookers, would bring out soapstone pizza stones and

heat defletors?

Unfortunately, there have been a significant number of reports of Kamado Joe soapstone items cracking and breaking, both during transport and during use. Are these problems specific to Kamado Joe soapstones or are they problems with all soapstone items? We decided to have a look for an alternate supplier of soapstone and also take the opportunity to play with some soapstone. The supplier that we settled on was Soapstone Products which produces quality soapstone products and of interest to us, specifically pizza stones. We ordered one of their pizza stones, so let's get started and take a look:

The Pizza Stone

For the purposes of this review, we ordered a 16" pizza stone:

Packaging

One of the complaints about the Kamado Joe stones is breakage during shipping. This is surprising since

soapstone, being a soft stone, is resistant to cracking. Photos that we have seen of the Kamado Joe packaging show

the stone just being protected by a very thin layer of styrofoam in a very thin box.

In the photos below, the box appears to be only about 2 to 2.5 inches in thickness.

The Kamado Joe stone itself is ¾ inches thick which means the styrofoam padding on top and below the

stone can only be about ⅞

inches thick at most:

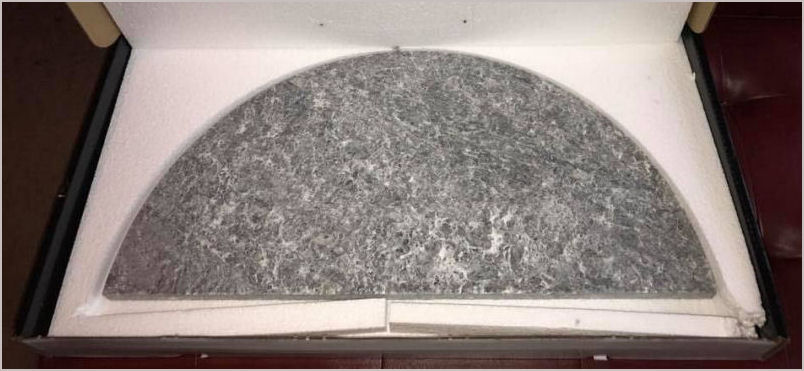

Contrast that with the Soapstone Products packaging for a 16-inch pizza stone. It consisted of a very sturdy 18" x 18" x 7" double-ply corrugated cardboard box. Inside, the bottom and sides were padded with 1-inch styrofoam. Inside this cushion of styrofoam was the stone wrapped in two layers of industrial strength bubble wrap. On top of the stone was a 3-inch layer of foam pellets. Generally speaking, the package was ready for just about any rough handling you can imagine. Below are photos showing the packaging.

And for another point of reference, it just so happens that we had also ordered a cordierite stone from Ceramic Grill Works. It was packaged in a sturdy 18" x 18" x 4" box with styrofoam peanuts surrounding the stone. Not as bomb-proof as the Soapstone Products packaging, but nevertheless, it arrived safely:

Curing

Soapstone Products recommends that you cure your stone, although they state that it isn't necessary.

The process for curing a stone is:

We decided to cure only one side of our stone so we could compare baking pizza dough on the two surfaces. As you can see in the photos above, the stone with the oil applied is darker and shinier than the photo we showed you earlier of the uncoated stone. Here is a photo showing the cured (left) and uncured (right) surfaces, side by side:

Cleaning

Soapstone Products recommends that for grill use, you clean your stone by using a wooden scraper/spatula or

a scouring pad. You can also use a metal scraper, but be careful not to scratch your stone. Minor scratches can

be removed with 120-grit sandpaper.

You can also clean your stone by placing the cooking side down and let the fire from your grill burn off any food residue. After baking a couple of pizzas, one on each side of the stone, there was a fair amount of oil left on the stone, so we used heat to clean it. We placed the stone on a raised grid and let the cooker get up to about 600°F for about an hour. You can see the results below:

There is a little bit of burnt residue on the right, but that is easily scraped off. In general, both sides looked almost like new. As you can probably see, the "cure" is no longer on the stone. We'd have to cure again if we decided we wanted the stone to be cured.

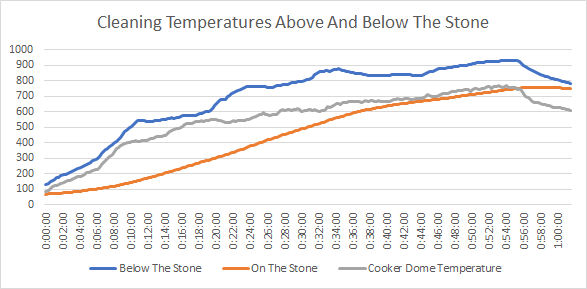

Warning Regarding High Temperatures With Soapstone: It should be obvious that if you place a thick heavy piece of soapstone over a fire, the underside of the stone is going to be exposed to higher temperatures than the top side. The following graph illustrates this quite dramatically. We placed a high-temperature Type K ceramic thermocouple underneath the stone. On top of the stone, with a small block of soapstone holding it down, we placed a high-temperature Type K wire thermocouple. And finally, we placed a Type K insertion probe thermocouple through the hole in the dome of the cooker to measure the dome/cooker temperature.

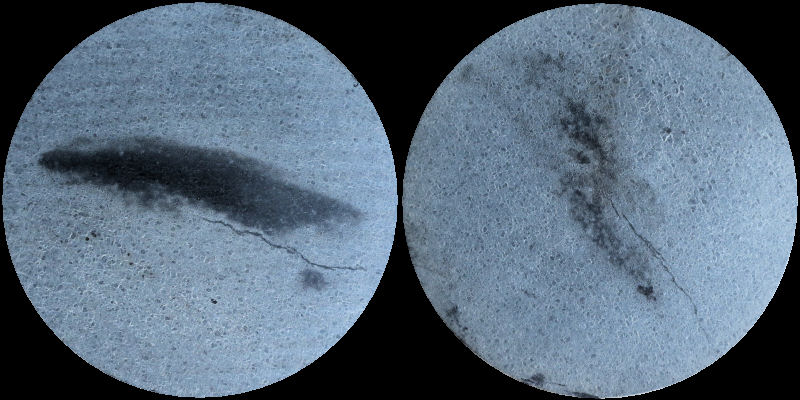

What the graph shows is that while the cooker and the stone reached about 750°F, the bottom side of the stone was exposed to 930°F which is pretty to close the the maximum temperature recommended for soapstone. And sure enough, by abusing our stone in this way, we managed to crack it. The stone didn't break, but as you can see, by wiping the stone with water and letting it dry, the crack becomes visible:

Photo showing the crack which formed in the stone after cleaning at too high a temperature.

How To Preheat Your Stone

Since we now know that the underside of the stone gets much hotter than the cooker temperature if it is exposed

to direct heat, it is important to protect the stone during preheating. First, you can assume that the temperature

below the stone can get up to 200°F higher than your cooker temperature, so choose a cooker temperature that

will keep this below-the-stone temperature at a reasonable level. Also, you might consider raising the soapstone in your

cooker so that you can place a ceramic stone or plate setter beneath it in order to shield the soapstone from the

intense direct heat of the fire. (Quality ceramic stones can survive much higher temperatures without cracking or

breaking than soapstone can.)

Making Pizza

It's a pizza stone, so let's take a look at using it for making pizza.

Preheating The Stone: Most sources indicate that for most pizza making, you should preheat your pizza stone to around 500°F. How long does that take with this massive piece of soapstone? We used a large Big Green Egg cooker to find out. Our setup was a plate setter with its legs up, a cooking grid on the plate setter, and finally the pizza stone on the cooking grid:

We heated the cooker up to around 500°F keeping it, for the most part between 500°F and 540°F. To measure the cooker temperature, we used a Type K thermocouple probe through the hole in the dome of the cooker. To measure the stone temperature, we used a Type K high temperature wire probe placed on the center of the stone and held in place with a small piece of soapstone.

Here's what happened:

The stone hit 500°F after 1 hour and 10 minutes. (At that point, we shut the vents on the cooker to let things cool down, hence the drop in the cooker temperature.) So, it is probably wise to allow your stone to preheat for at least one hour if you don't have the means to actually measure its temperature.

If you are wondering how a ceramic pizza stone compares to a soapstone pizza stone, well we have you covered. We repeated our warmup experiment with a 16-inch ceramic stone that isn't as thick as the soapstone pizza stone and only weighs 9 pounds 5 ounces, versus the 16 pound soapstone pizza stone:

The ceramic stone reached 500°F in only 52 minutes versus 70 minutes for the soapstone pizza stone. And as you can see, they cooled at about the same rate inside the cooker with the vents closed and the fire dying.

It is probably worth a quick note about charcoal consumption. You are going to use a lot of charcoal just preheating your stone, so make sure you start with plenty. In our test above, we started with a slightly mounded Kick Ash Basket. We'd estimate that we used between ½ and ⅔ of the charcoal.

Cured or Uncured? As you saw earlier, we cured one side of the stone and left the other side of the stone in its natural state. We baked pizza dough on each side to see how they compared and frankly, we didn't see a difference. You will probably end up "curing" the stone anyway if you use it for making smashburgers or searing scallops, etc.

Crust Results We cooked two pizzas made from Urban Slicer Pizza Worx Neopolitan Style Pizza Dough mix. We baked one pie on a 500°F preheated stone, and one on a 430°F preheated stone. Here's how the crust turned out:

500°F stone after 5 minutes.

500°F stone after 6 minutes.

500°F stone after 7 minutes.

430°F stone after 5 minutes.

430°F stone after 7 minutes.

Making Burgers

Another use for these soapstone pizza stones and heat deflectors is searing. Folks like to sear scallops

and steaks, and also make smashburgers:

On our first attempt, the burgers stuck. The stone wasn't hot enough and the meat was lean. The photo above shows our second attempt. The stone was 400°F and could have been a bit hotter. We used 85/15 beef and also used a little clarified butter on the stone for lubrication. Much better.

Since our stone is now cracked after our abusive clean burns that we described above, we decided to use a plate setter, legs up, underneath the soapstone in order to protect it from extreme heat. We also used a SMOBOT temperature controller to keep the cooker under control while we did some chores. The burgers turned out fine, but it took about an hour for the stone to heat up and used a lot of charcoal.

So, we don't see much benefit to using a soapstone for searing. It takes a long time to preheat the stone, it uses a lot of charcoal to preheat the stone, and due to the temperature differential between below and above the soapstone, there is a risk of cracking your stone. Cast iron would seem to be a better alternative. Here is a graph showing the warmup time of a cast iron plate setter versus a ceramic pizza stone:

Recommendations For Using Your Soapstone Pizza Stone

Here are a few notes, observations and guidelines for using your soapstone pizza stone:

Conclusions

Based upon our experience with the soapstone pizza stone, it's pretty clear that the reason for Kamado Joe

stones getting broken in shipping is inadequate packaging. We have no reason to believe that Kamado Joe

soapstone products are made from an inferior grade of soapstone and would have no problem using their

stones. Since Kamado Joe will replace broken stones,

the only downside is the inconvenience of having to wait for a replacement. However,

a stone could get damaged in shipping and have a crack that isn't immediately visible. This crack might

subsequently fail during use. It is certainly worth your while to take a damp rag and wipe a new stone down

with water. As the stone dries, any cracks that have made it to the surface of the stone will be easily

visible.

As for stones cracking during use, we feel that this is more likely due to failure to understand the thermodynamics of using a heat deflector in a kamado-style cooker. As we have seen, the bottom side of the stone can be exposed to temperatures far higher than the top of the stone, temperatures that can damage soapstone. You would be well advised to heat the stone slowly and at a lower temperature than what you think is safe, and also to use a ceramic heat deflector below the soapstone if you are using really high temperatures. Yes it will use more charcoal and take longer to preheat the stone, but it will help to prolong the life of your soapstone.

Availability

¾-inch round pizza stones are available in 10, 12, 14, 16, 18, and 20-inch sizes at the Soapstone Products web page.

¾-inch 10" x 15" rectangular stones are also available. All stones are also available in 1-3/16" thickness.

Soapstone Products will also quote prices for custom sizes and shapes, such as the half-moon heat deflectors sold by Kamado Joe.

Contact Information

Soapstone Products

P.O. Box 517

Milltown, New Jersey 08850

Phone: (732) 828-7000

Fax: (609) 737-1999

Email: info@soapstoneproducts.com

Web: www.soapstoneproducts.com

Facebook: www.facebook.com/SoapstoneProducts/

You can support this website by shopping at The Naked Whiz Website Store and Amazon.com

|