|

|

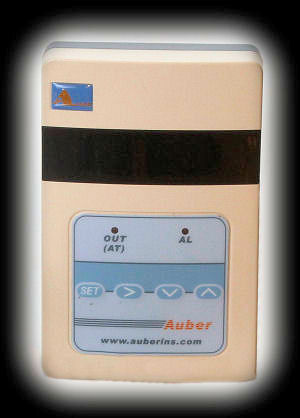

You may remember that the original BBQ Guru Competitor had a "Good Neighbor Feature" which allowed you to disable the alarm so as not to disturb your neighbors. This feature is implemented on the Auber Instruments controller by virtue of the fact that you can disable the alarms. Blower operation is indicated by the red LED labled "OUT (AT)" as described earlier. The Auber Instruments controller has an internal memory which retains all settings during a power loss. When power is returned to the unit, it will continue to operate as it did before the power loss, with the target temperature and settings retained. What is Ramp Mode? It doesn't really matter since the Auber Instruments controller doesn't have it. However, more advanced models have a clever mode in which the controller will lower the cooker temperature once the meat gets close to being done. As the meat temperature rises closer and closer to the target temperature, the controller continues to lower the cooker temperature. Ultimately, when the meat temperature reaches the target temperature, the cooker will also be at the meat target temperature. As a result, you can hold your meat at your target temperature as long as the cooker has fuel left to burn. But like we said, this controller doesn't have it. To implement Ramp Mode, you need to monitor both the food temperature and the cooker temperature and of course, the Auber Instruments controller only has one probe which monitors the cooker temperature. The Auber Instruments controller allows you to enter a pit setpoint down to a temperature of -300°. (Yes, we said -300°! We won't go into it in our review, but this controller can be used to control cooling processes as well as heating processes.) Therefore, if you think you can build a fire small enough, this controller will attempt to control your fire down to very low temperatures. Just remember, though, that in order for the Auber Instruments controller to control the cooker at lower temperatures a good seal on your cooker is very important. Too much ambient airflow will prevent the controller from keeping the fire low enough to maintain a low temperature. The BBQ Guru controllers have a feature called "Adaptive Control", first introduced with the BBQ Guru DigiQ II controller. The BBQ Guru describes it as a: "...full-time adaptive control algorithm [that] learns your pit to control better stability/accuracy." Over time, the unit learns how much effect the blower has so that it can more accurately and intelligently decide how long to run the blower when it needs to adjust or maintain the cooker's temperature. So for example, if the unit signals the blower to operate at 30% and it sees that the temperature overshoots a bit, it will gradually learn to run the blower at 20% instead. This "learning" is done on every use and it does not get "remembered" from one use to the other. The Auber Instruments controller comes from the factory with all the magic numbers inside preset and it should operate just fine as it comes. However, if you find that your cooker isn't getting controlled as well as you would like, the Auber Instruments controller has a feature called "Auto Tune." Rather than automatically try to learn your cooker on every use like the BBQ Guru's Adaptive Control, the Auber Instruments controller's Auto-Tune procedure must be run before you wish to use your cooker. During Auto-Tune, the controller will heat up your cooker and then allow it to cool. It will do this several times in order to learn how your cooker responds. The controller will then determine the values for the internal parameters used to control the cooker and use them instead of the factory preset values. These values will then be remembered until you manually reset them. So unlike the BBQ Guru, this unit will not learn a new cooker as you use it. If the parameters chosen for one cooker don't work well with another cooker, then you will need to rerun the Auto-Tune process. It should be noted also that the Auto-Tune process can take a long time if your cooker takes a long time to cool down on each test cycle. The Auber Instruments controller does not have any sort of Open Lid Detect feature, per se. However, since it is a PID controller which attempts to take into account previous, current and predicted results, it does in a way have an Open Lid Detect feature built in. Or does it? We performed the following test twice, once using the factory set parameters and once after using the Auto-Tune feature to tune the controller to our cooker. We had the cooker running stable at 300°, opened the lid for 30 seconds, then closed the lid and watched. Using the factory parameters, the cooker dropped to 203° with the lid open. It then recovered to 310° after the lid was closed. The controller then allowed the temperature to drop to 282° before slowly bringing the cooker back to 300° in about another 4 minutes, where it remained stable. After having used Auto-Tune to tune the controller to our cooker, however, the performance was much worse. The temperature dropped to 206° with the lid open and rose back to 315° after the lid was closed. The controller then puzzlingly allowed the terperature to drop to 269° before ever so slowly bringing the cooker back to 300° after about 15 minutes. We'll talk a bit more about Auto-Tune performance later, but suffice it to say that using the factory parameters appears to give much better performance when opening the lid. The results we obtained with the factory parameters was comparable to what we observed with the BBQ Guru NanoQ controller with the Open Lid Detect feature enabled. The Auber Instruments controller uses a PID control mode as the default. What's PID? Here's what is in Wikipedia: "The PID controller calculation (algorithm) involves three separate parameters, and is accordingly sometimes called three-term control: the proportional, the integral and derivative values, denoted P, I, and D. [...]these values can be interpreted in terms of time: P depends on the present error, I on the accumulation of past errors, and D is a prediction of future errors, based on current rate of change. The weighted sum of these three actions is used to adjust the process via a control element such as the position of a control valve or the power supply of a heating element."A little more reading reveals that it is used in feedback loop method which turns out to be a pretty good method of controlling a process when you don't have good knowledge about the process itself. However, the Auber Instruments controller has two other control modes that you can use if you so choose:

|

You can support this website by shopping at The Naked Whiz Website Store and Amazon.com

|