|

|

The display on the FLame Boss 500 is a backlit LCD display consisting of 4 lines of 16 characters each. The display measures approximately 2½" by 1". The display contrast can be adjusted, although you probably will never want to do so.

All the connections are on the bottom edge of the control unit. From left to right are the plugs for the power cord and blower. Continuing to the right you will see the sockets for the pit probe followed by the three meat probes.

Because the front of the Flame Boss 500 unit overhangs the connections in order to shield them somewhat from rain, Flame Boss has come out with new probes, a new power supply and a new blower that have straight plugs, versus the older versions which have angled plugs.This makes connecting all the wires more convenient. There is no reset button on the Flame Boss 500 and you cannot do a factory reset via the menus. The Flame Boss 500 is powered by 12V DC. It comes with a power adapter that can be used with 100-240 VAC, 50-60 Hz. The power adapter has a 5-foot cord. Since the unit has a standard 5.5mm 12V barrel socket on it, you also have a number of alternatives for powering the Flame Boss 500. There is a 12V rechargeable power supply available from Flame Boss. You can also use an automobile jump start battery with a cigarette plug to power the unit. And another alternative is the Auber Instruments 12V DeWalt Battery Pack Adapter that we recently reviewed.

The Flame Boss 500 comes with two temperature probes, one for the pit and one for the meat. These probes have a braided stainless steel cable and should be good up to 450°F. (Note that there are different limits stated in different locations. The literature that comes with the controller states that they are intended to be used at 400°F or less, while the Flame Boss web site says they can be used used up to 475°F.) Notice that the meat probe has a red plug. If you decide to buy additional meat probes, you have the option of getting probes with orange or green plugs to help identify the different probes. Be careful not to kink the cables and it is probably wise to protect any junctions between cables and probes from moisture. The Flame Boss 500 now comes with two probe cable organizers to help you store your probes without kinking the cables.

The probe and the wire should be shielded from direct radiation from a hot fire. Do not let it come into direct contact with flames. If you need to shield the wire, you can place a layer of aluminum foil beneath it. Also, having the pit probe itself exposed to direct radiant heat can cause it to register a temperature which is higher than the air temperature in the cooker, and thus fool the controller into cutting back on the fire. An alligator clip is provided with the pit probe which you can use to clip the probe to your dome thermometer or the food grid, as you see fit.

Unlike many of the controllers on the market, Flame Boss probes are not thermocouples. They are platinum RTD sensors. What's that? Well, if you don't want to know skip the next 3 paragraphs. First of all, a thermocouple works on the Seebeck effect. When two ends of a conductor (wire) are at different temperatures, a voltage is created between the two ends. The magnitude of the voltage depends on the temperature difference between the two ends. The magnitude of the voltage also depends on the metal that the wire is made from. If you take two conductors made from different materials, there will be a different voltage created in each conductor. Different types of wire will thus generate different voltages for the same temperature difference. Then if you connect the two conductors at one end, the two voltages will add producing a voltage across the two conductors that varies with temperature. With me? If you know the materials, then you know the voltage generated for each temperature and this then gives you the DIFFERENCE in temperature between the two ends of the pair of conductors. Finally, you put a thermistor inside the meter that the probe plugs into to tell you the temperature of that end of the pair of conductors. Voila! You know the temperature of one end of the pair of wires, and you know the temperature difference between the two ends. Therefore you know the temperature of the other end! Simple, eh?Still with us? Good. One note of warning before we proceed. The plugs used on these probes are the same as the plugs used on probes made by at least one other manufacturer of temperature controllers. Thermocouples and RTD probes are not plug compatible, so just because the plug looks the same, don't be tempted to use the probes from another manufacturer. We measured the room temperature and the temperature of boiling water using the Flame Boss 500 controller. Using our boiling point calculator to determine the boiling point of water in our locaton (212.1°F), we then measured the temperature of boiling water with each of the probes:

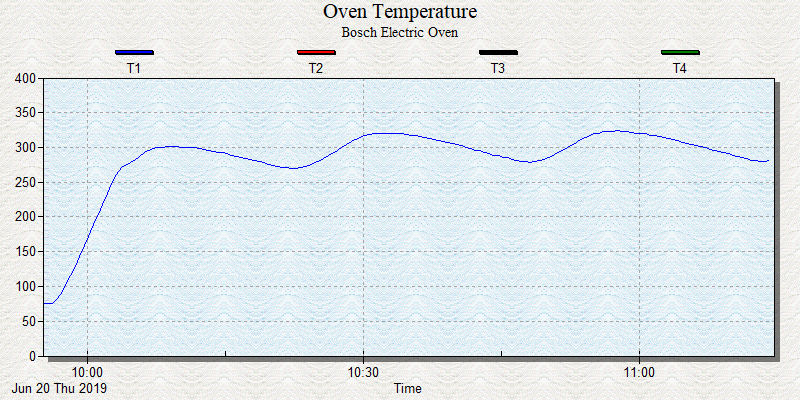

As you can see, all probes recorded room temperatures that were less than 1.0°F from the actual room temperature. As you can also see, the measurements for boiling water were almost within 1.0°F. So, all probes were well within the error range for a platinum RTD probe. 1.0°F is insanely close for the purposes of cooking and controlling the temperature of a cooker. And compared to the 50°F swing that is typical of most kitchen ovens, 1.0°F is a tiny blip. How tiny? Well here is how well our $2200 Bosch oven holds 300°F:

That's a 43°F swing on the last oscillation. Again, an error of a few degrees on your pit temp is irrelevant. As we previously explained, platinum RTD sensors typically require no calibration, so there is no calibration procedure provided in the Flame Bosss 500 manual. If your probes consistently read off by a significant amount, you should contact Flame Boss support to investigate. |

You can support this website by shopping at The Naked Whiz Website Store and Amazon.com

|

.